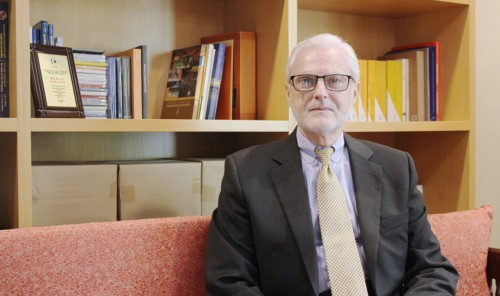

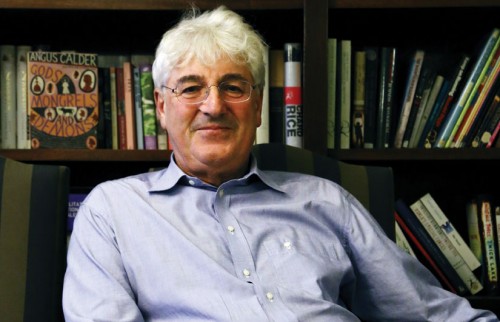

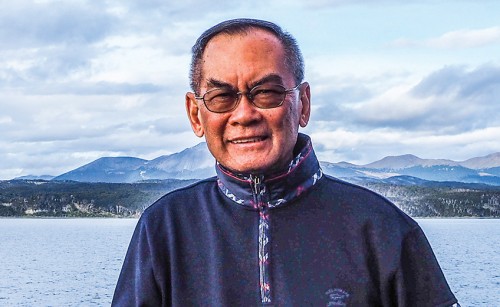

Keith Curnow, who comes from northeast England, spent a lifetime working in the petrochemical industry, finally as a shipping manager for the German multinational chemical company, BASF. After retirement, he moved to Thailand and is now sharing his skills and knowledge to help develop and manage his new home, Chuan Chuen Parkville Village. Recently, Keith sat down with Elite+ magazine to share some of his adventures and his decision to settle in Bangkok.

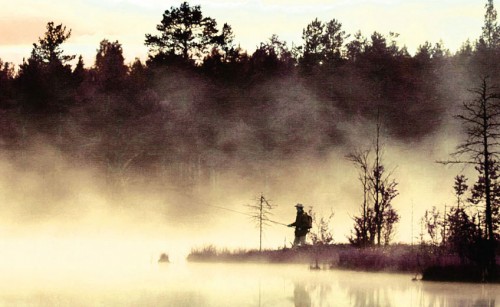

Keith was born and grew up in Loftus with his two older brothers, who both went on to very successful business careers. Loftus is a small village on the edge of the beautiful North Yorkshire moors, with a population of just 6000 people. His father was a bricklayer for the local steelworks and his mother worked in the local school’s cafeteria. For enjoyment, they loved walking the countryside with their dog and Keith says, still today, he thinks like a country boy, even though he has travelled and experienced much of the world.

At the young age of 16, Keith completed his studies at Guisborough Grammar school and left home to begin to work as a mechanic for the Royal Navy, because of his interest in engineering. After six months, he joined the Imperial Chemical Industry (ICI) where he was accepted in to their apprenticeship program. “This was my introduction to the petrochemical industry where I spent my whole working life until I retired at the age of 61. I wasn't in the paints division, but worked on the petrochemical side, and during my apprenticeship I was given the chance to work in many different chemical processing plants, spending six months at each, which enhanced my knowledge and hands-on experience as I had the chance to work at almost all of their different sites.”

Keith then turned his attention to the maintenance and repair of ICI’s own HGV wagons and chemical tankers, designed to carry bulk liquid chemical loads. He would repair every aspect of the units and trailers and their complicated systems that include gearboxes, compressors, PTO's and relief valves to name a few. Keith was promoted to shift foreman after only four years. After 11 years, when ICI began to downgrade and sell many of its plants, to ensure he would continue to have employment and earn enough to care for his wife and children, he decided to become a chemical tanker driver, delivering chemicals all around the United Kingdom, but even though this job was better paid than engineering, it also had its drawbacks.

“With this job, I needed to leave home on Monday morning and come back home on Friday, which left me little chance to spend time with my children. Nevertheless, during weekends we made the best of our time together. I lived this kind of life for 10 years, but after all this time as a tanker driver, I did not want to miss any more of my family life and so decided to end my driving career and I got a job working for another German chemical transport company, Hoyer.”

Hoyer had invested in a state-of-the-art chemical tanker cleaning plant on Teesside, and Keith was made the manager of this chemical cleaning site. “Normally when transporting any liquid chemical from point A to point B and after unloading, these tanks need to be used to transport another liquid chemical and so, they have to be cleaned thoroughly, unless the next product is compatible. You do not want any cross contamination, as this can have dire consequences, not only being dangerous because of a chemical reaction, but also monetarily because of putting huge storage tanks out of spec. Therefore, they need to be perfectly cleaned to meet recognised industrial standards. I supervised the entire process and because of my background, I had a very deep understanding of what had to be done and why.”

Possibly because Keith had developed a job wanderlust, again he decided to move on after 12 years. Following a friend’s recommendation, he applied to and was hired by SGS, who then subcontracted his services to the German multinational chemical conglomerate BASF, which operates in more than 80 countries world-wide with six integrated production sites and 390 addition production sites in Europe, Asia, Australia, the Americas and Africa. While Keith had never worked in the shipping industry before, he managed all imports and exports via ships of liquid and gas chemicals, HMD (Hexamethylenediamine) ACN (Acrylonitrile), Sulphuric acid and Propylene Gas. The main danger of HMD is its very corrosive nature, whereas ACN is toxic by inhalation, absorption and ingestion with Cyanide being part of its chemical makeup. Keith stayed with SGS and BASF, or INEOS as it is now called, until he retired and moved to Thailand.

Today, as a member of the management board at Chuan Chuen Parkville Village, he is sharing his knowledge and expertise to help develop the safest, most comfortable and complete home and environment for the entire community. “One of my main responsibilities right now is very similar to the work I was doing before I retired. I supervise the management of the dosing systems for our ponds and swimming pool. A dosing system is an automated chemical injection system to supply reagents into the wastewater network to control septicity and odour emissions.

The system comprises motors, pumps, chlorine and chemical injectors as well as those systems for ozone and oxygen. This estate is a very effluent environment. It has a high amount of storm drains which has to be regularly maintained as the many lakes are all directly linked to the effluent plant where rubbish, silt and algae are separated and disposed of, producing clean water that is returned to the lakes. We also have a new swimming pool which must be carefully and meticulously maintained. All these systems are very similar to what I have worked on back home in England. The hardest thing for me to get accustomed to is the Thai attitude towards regulations and safety. “In England, people take safety very seriously. I was part of a team within BASF, or INEOS as it is known today, that regularly updated working procedures and therefore, safety is my second nature. I feel it is a very important and integral part of everyday life. However, in Thailand, people are more relaxed about these concerns, which can be quite dangerous, in my point of view. So, I’m trying to instil the importance of safety with those I am now working with.

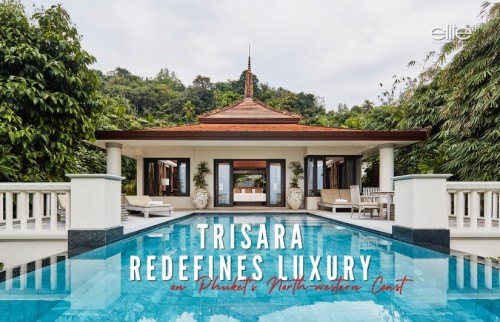

One of Thailand’s great attractions for Keith is the Thai easy-going nature. He says, “While in England, people are very punctual and straight. Thailand to me is like the Spanish word "manyana", or should I say, "mai pen rai krup", where people don't seem to mind when things are out of order. This is why I say, things are very easy going here. So, when I decided to live in Thailand, I knew I would have to adapt, and now I am very happy with this attitude and lifestyle. However, we must not and cannot allow any safety standards to slip.”

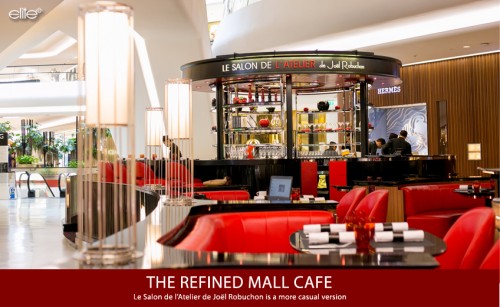

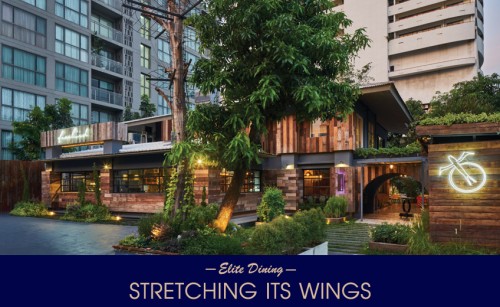

Keith, together with his other board members, are looking to the future as they continue to craft their village. Soon, the new swimming pool will open, which will be followed by a restaurant, café and shops, where they can relax, dine or just enjoy a good cup of coffee while they enjoy the view.

Keith closed by saying, “I would like to improve the village for the next generation, keep improving the facilities and systems so I can hand down my jobs to the next generation, and they won't have a difficult time maintaining the village. I want villagers to see that we can really help make our village grow and become a happy place to live.”